Services

From start to finish we have the capabilities you need.

The Expertise and Tools Your Project Needs

Advanced Molding, Stamping and Laser Processing services for your components and medical devices.

Molding

With thousands of resins to choose from, we create effective and repeatable molding solutions for our customers using the latest technology. Our molding capabilities include Insert, Micro, Micro-Insert, Liquid Silicone, and Two-Shot. We also provide assembly and secondary operations for a range of medical devices.

Stamping

We have the flexibility and know-how to handle any stamping job, from a few dozen pieces, up to millions of components. Our capabilities include Stamped Component Manufacturing, Assembly, Secondary Processes, and In-House Tool Design, Build & Maintenance.

Laser Processing

We provide precise solutions for a wide variety of medical device technologies and materials. Our laser services include Cutting, Welding, Drilling, Wire Stripping/Ablation, Profiling & Skiving, Marking and Nitinol Processing.

A Streamlined Approach

Cretex Medical has an integrated solution for your molding, stamping and laser processing needs. Component & Device Technologies (CDT) is how we’ve streamlined JunoPacific, Meier Tool & Engineering, and Spectralytics. By leveraging three industry-leading medical device manufacturers into one company, we have the expertise and scale to take your project from idea to prototype to high volume production.

When you work with Cretex Medical | CDT, you can count on a solution that maximizes efficiency and quality to help you more easily bring your products to the patients who need them.

Customer Centricity in Everything We Do

Our customers range from small start-ups to global multi-billion-dollar medical device manufacturers. We can support your project whether it’s a new product or proof of concept, or a fully globally launched medical device.

We tailor your experience to your needs. In addition to special teams who collaborate with you through the early design cycles of a new product, we also have dedicated resources for continuous improvement and volume scale-up for sustained manufacturing.

We Specialize in Going the Extra Mile for You

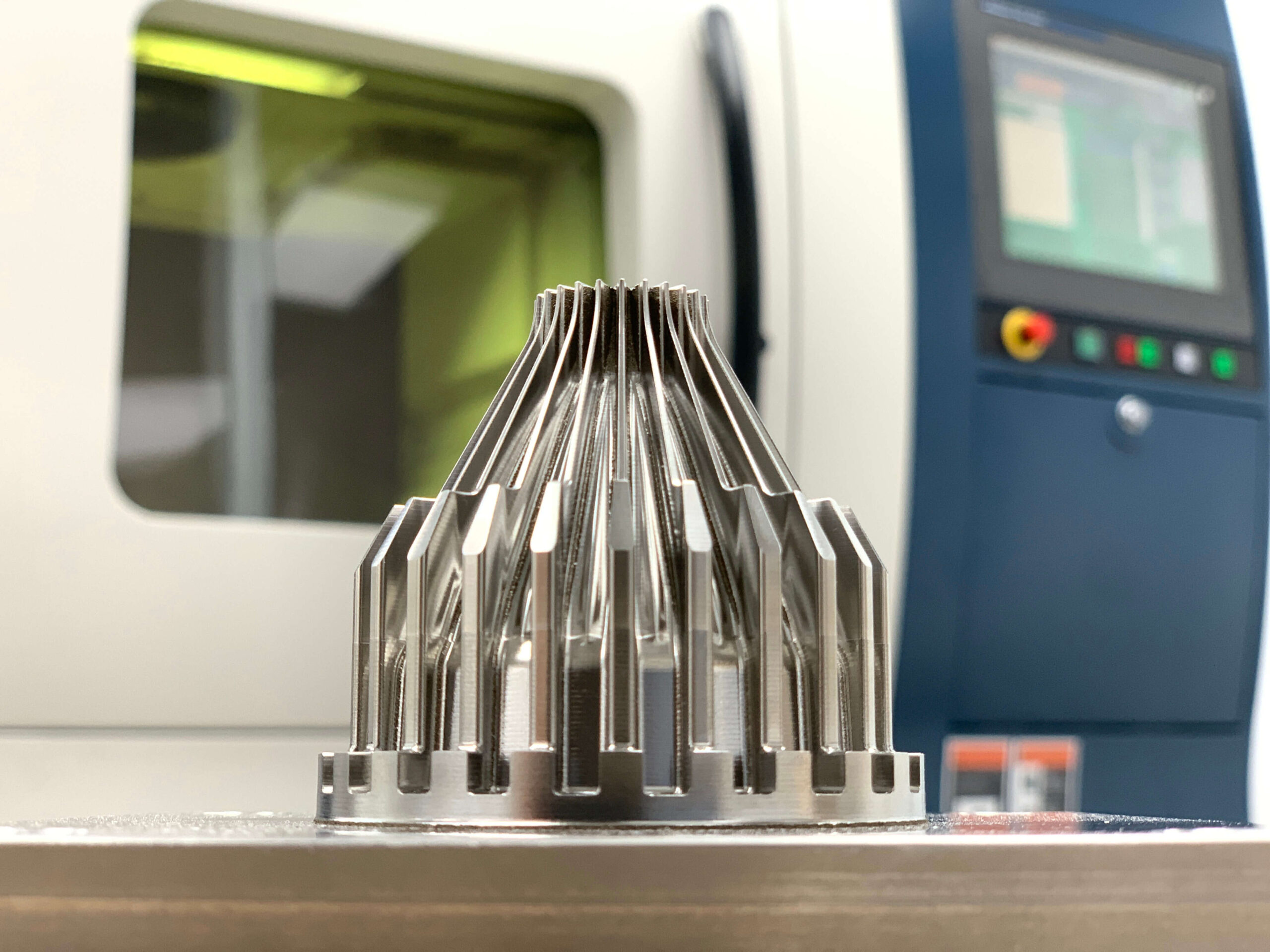

Partnership Paired with Innovative Technology

One of our customers was facing a fast-approaching 501(k) FDA deadline and needed a part that would take most medical device manufacturers 9-12 weeks to deliver (molding a new part and design verification of equivalent parts). With our onsite metal additive printer, we were able to design and build their mold tool in 2 weeks and quickly produced verification parts for testing. We accelerated delivery by almost 2 months! As a result, the customer met their deadline, received FDA approval, and can now get their products to the patients who need them.