Secondary Processing

Comprehensive Contract Manufacturing

Our Cretex Medical companies have developed in-house secondary capabilities as well as a network of approved suppliers to offer a complete range of finishing operations to best meet your medical device requirements.

Producing a Finished Medical Device

Our goal is to provide you with a complete, finished device.

With access to dozens of post-production processes, you don’t have to waste time moving your parts from one supplier to another, which means you can get your products in the hands of those who need them more quickly.

Our list of secondary operations continues to grow, but here is a quick look at some of our most popular services:

- Cleaning & Passivation

- Electropolishing & Anodization

- Tumbling & Blasting

- Buffing & Deburring

- Dragging & Mechanical Polishing

- Bending

- Plating

- Heat Staking

- Epoxy & UV Curing

- Polymer Reflow

- Ultrasonic & Laser Welding

- Laser Marking & Etching

- Laser Welding, Drilling and Ablation

- Over Molding

- Pad & Silk Screen Printing

- Kitting, Packaging & Labeling

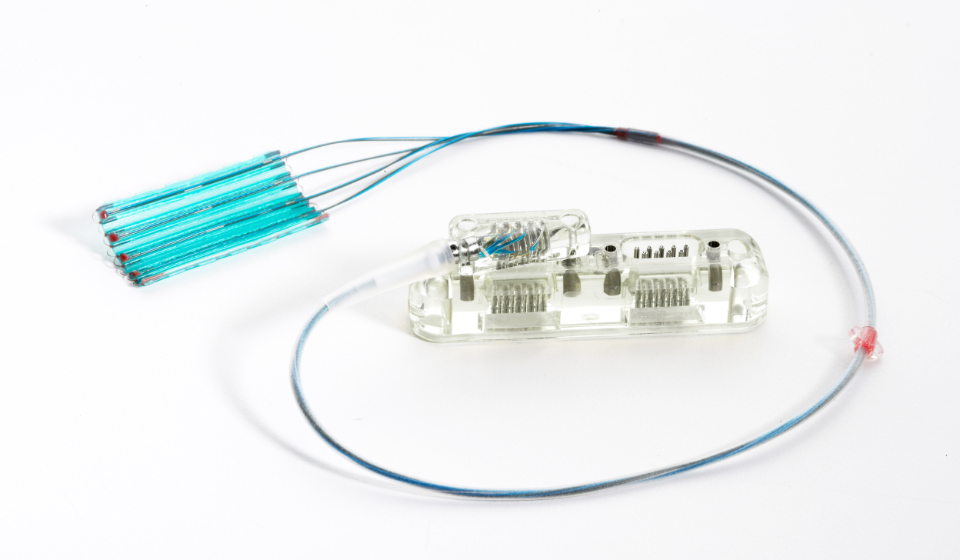

- Sub-Assemblies & Complete Device Assembly

Push your project further, faster.

Our Businesses

Laser Processing, Precision Stamping and Molding Technologies

CDT integrates manufacturing and engineering expertise across a broad range of capabilities to produce high-precision components and assemblies.

Finished Device Assembly, Kitting, Packaging and Sterilization Services

QTS offers reliable end-of-line services including validated cleaning, sterile packaging, and complete kitting and labeling of your devices.

Precision Machining, Additive Manufacturing and Metal Fabrication

rms is a contract manufacturer of high-quality, tight-tolerance implantable devices, components, assemblies, custom instrumentation, metal enclosures, and cases & trays.