Additive Manufacturing

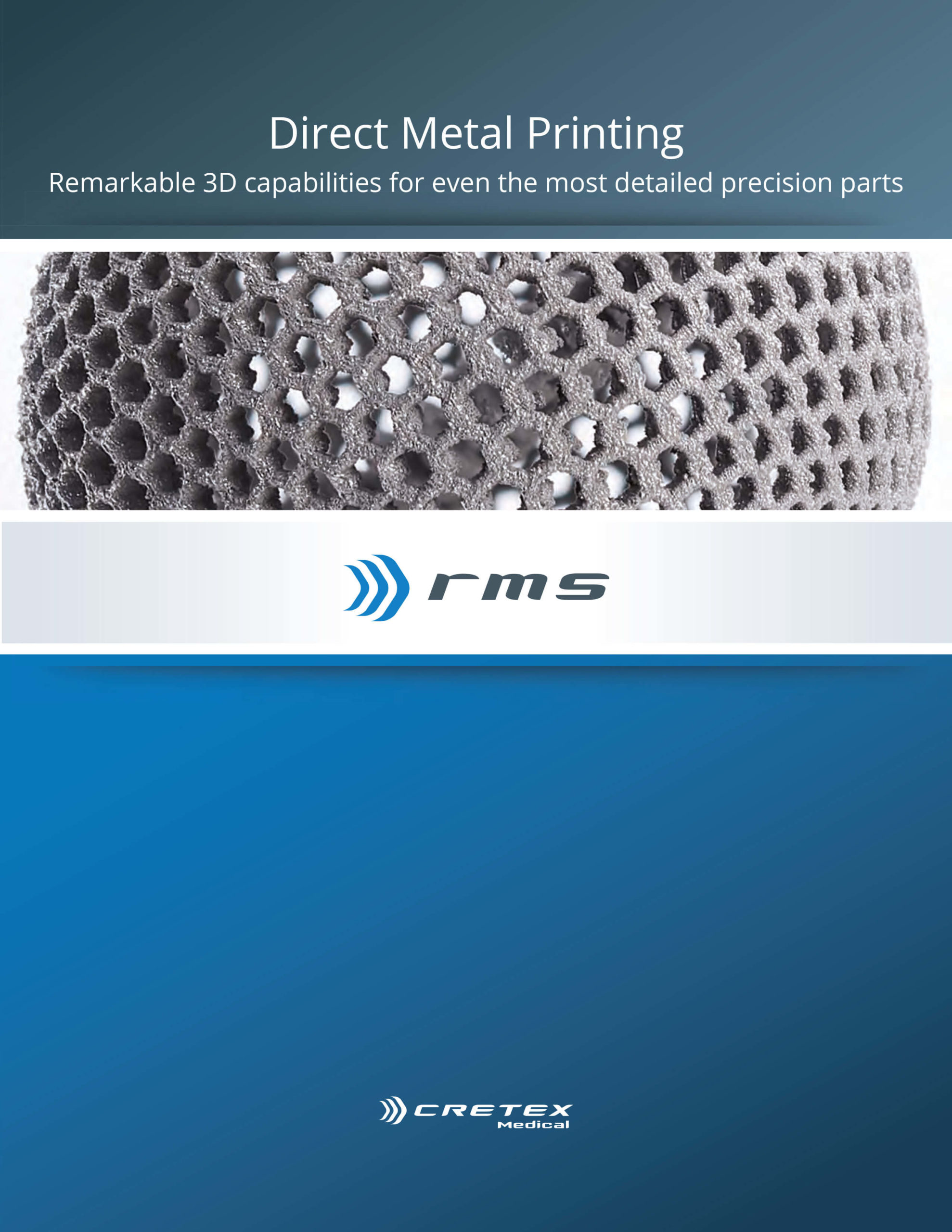

Direct Metal Printing

Cretex Medical | rms offers direct metal printing (DMP), also known as 3D printing or additive manufacturing, to support the development and production of advanced orthopaedic implants. Our early investment in DMP allows you to leverage our cutting-edge technology, advanced expertise, and partnerships with key equipment manufacturers.

We have 30,000 sq. ft. dedicated solely to our additive printing and support equipment. Our machines run day and night totaling thousands of production hours per week.

We offer full support for your printed Titanium implants from design for manufacturing and assembly, through process optimization, high-volume production and secondary processing. Partnering with us reduces your risk and lead time so you can launch and scale efficiently.

Cretex Medical | rms

Direct Metal Printing

Supporting your Project with 3D Polymers

At Cretex Medical, experts across our operating companies leverage polymer additive manufacturing to develop prototypes, support fixtures, and training tools, ensuring you achieve the best design for your project. By deploying multiple 3D printing technologies, we optimize print function selection and lower your costs and time to market.

We currently offer:

- Fused Deposition Modeling (FDM)

- Stereolithography (SLA)

- Polyjet

Are you looking for an additive partner?

Our Businesses

Laser Processing, Precision Stamping and Molding Technologies

CDT integrates manufacturing and engineering expertise across a broad range of capabilities to produce high-precision components and assemblies.

Finished Device Assembly, Kitting, Packaging and Sterilization Services

QTS offers critical end-of-line services for medical device OEMs including finished device assembly, packaging and sterilization management.

Precision Machining, Additive Manufacturing and Metal Fabrication

rms is a contract manufacturer of high-quality, tight-tolerance implantable devices, components, assemblies, custom instrumentation, metal enclosures, and cases & trays.