Prototyping

Prototypes for Your Medical Device

There is no better way to assure the fit and function of your components, implants, instruments and delivery systems than to have a live prototype in your hands. Cretex Medical understands how critical it is to your design process to have quick access to prototypes in order to remove any doubts about performance and achieve your launch dates.

New Product Introduction for Molded Parts

When you partner with Cretex Medical | CDT for your molded components, you are engaging with a focused NPI team of engineers, machinists, designers and manufacturing experts to develop and launch your products on schedule and within budget.

We offer quick and flexible development of tooling solutions for prototyping and support low-to-mid volume production. Depending on the part complexity, our NPI team is committed to delivering your parts as soon as 48 hours from the receipt of the final design.

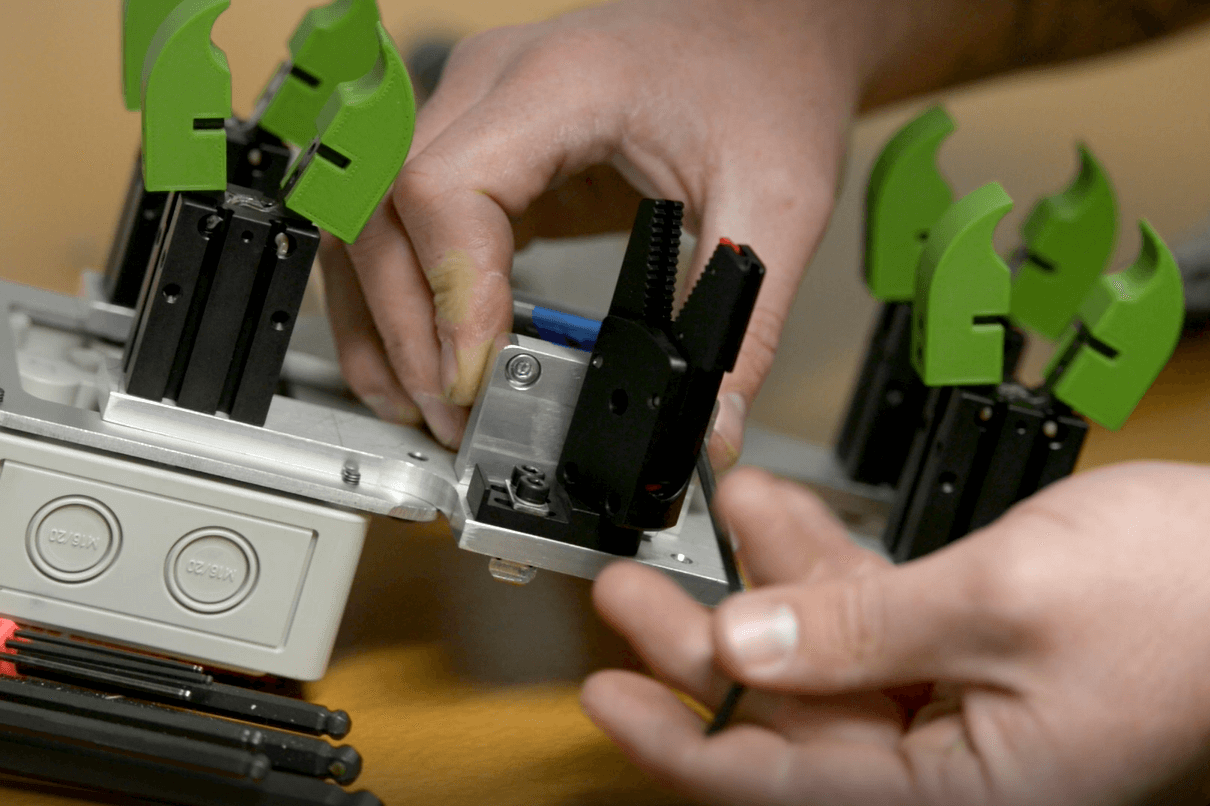

Optimize Your Design with Our RapidStamp Program

Cretex Medical | CDT‘s state-of-the-art prototyping and development center allows you to work closely with our engineers and toolmakers to test design iterations of your precision stamped parts. This enables you to perform fit checks, test performance, and identify and correct potential issues before the design is finalized. Our experts help optimize your designs and ensure your production goes smoothly.

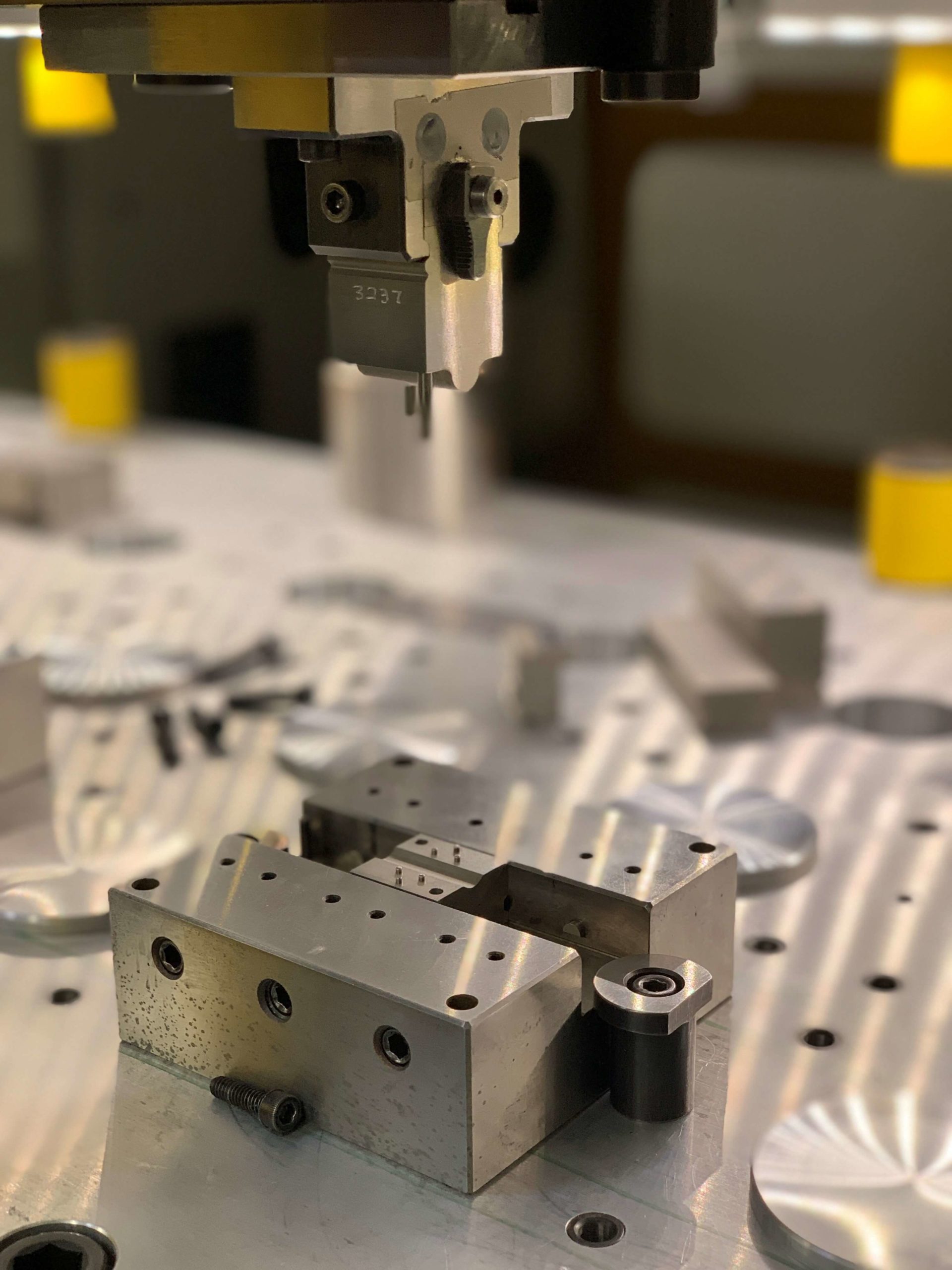

Machining & Metal Fabrication Prototypes

Precision machined prototypes supplied by the Cretex Medical | rms facilities are produced using the same manufacturing equipment, tooling, processes and programmers used to manufacture market-released products, ensuring your critical prototypes are made to production equivalent standards. By using the best technologies and manufacturing talent available during the prototyping stage, we can assure success in every phase of your product life cycle without sacrificing short lead times. We offer prototyping for implants, instruments and cases & trays.

Prototypes of Your Laser Processed Components

Have confidence with iterative designs and accelerate time to market with Cretex Medical | CDT‘s product development services. Our Development Center ensures you meet or exceed deadlines with dedicated technical experts and cutting-edge laser equipment. Once you have validated and tested your design, we have the expertise and equipment to take your project into production quickly.

Submit your project details.

Our Businesses

Laser Processing, Precision Stamping and Molding Technologies

CDT integrates manufacturing and engineering expertise across a broad range of capabilities to produce high-precision components and assemblies.

Finished Device Assembly, Kitting, Packaging and Sterilization Services

QTS offers critical end-of-line services for medical device OEMs including finished device assembly, packaging and sterilization management.

Precision Machining, Additive Manufacturing and Metal Fabrication

rms is a contract manufacturer of high-quality, tight-tolerance implantable devices, components, assemblies, custom instrumentation, metal enclosures, and cases & trays.