Process Validations

We Don’t Just Verify, We Validate

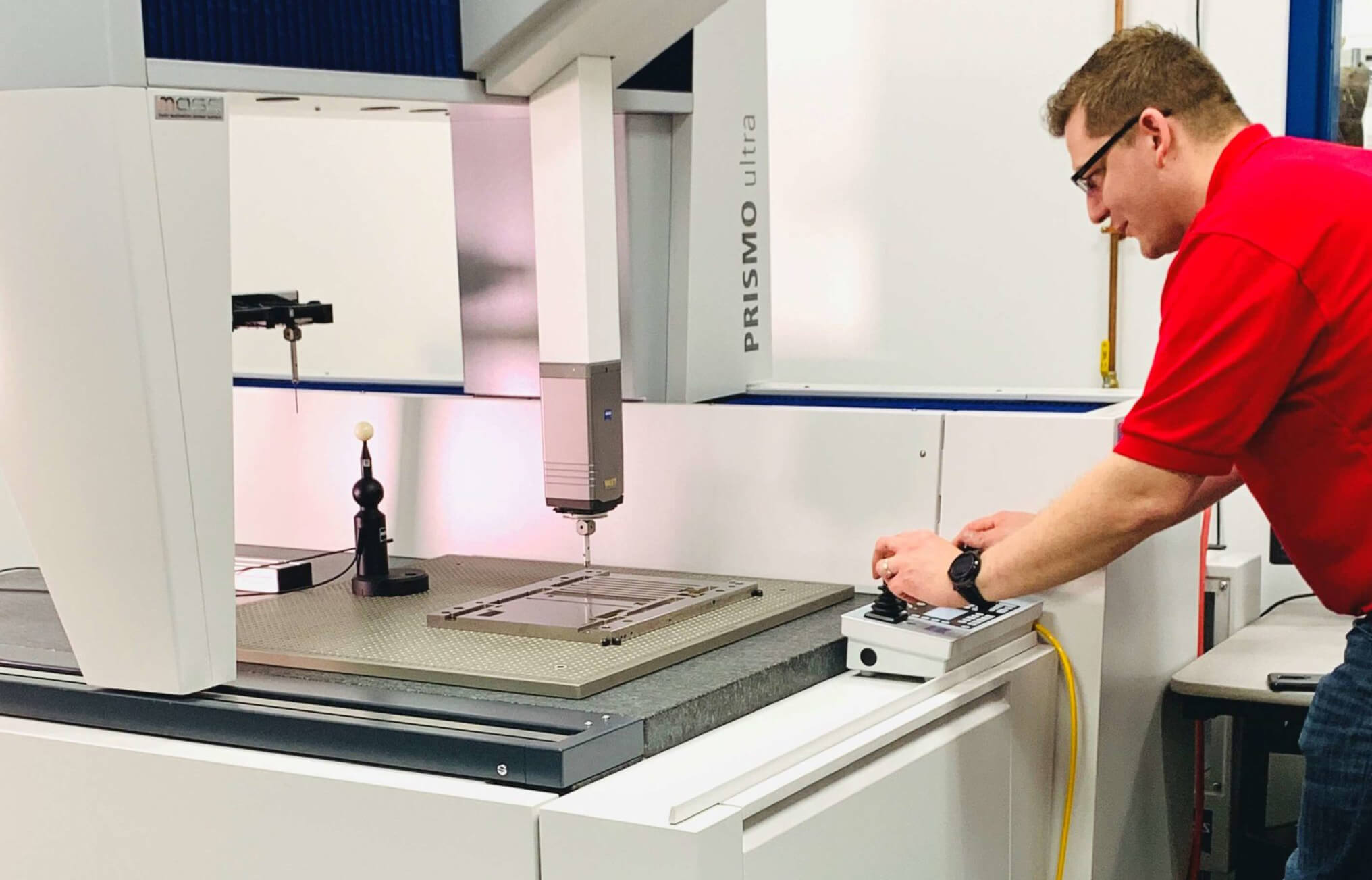

Validation of manufacturing processes is a fundamental requirement to assure the best possible outcomes are achieved for every production run. When it comes to product quality and patient outcomes, there can be no compromise.

Cretex Medical ensures your medical components and devices meet your exacting requirements by performing thorough validations of our processes. We go beyond just verifying that we are meeting your specifications, we validate our processes, procedures and equipment to make sure we are producing the same quality parts every time.

We validate all aspects of our manufacturing processes from initial machining, molding and stamping of components, to final cleaning procedures and performing thorough package and sterilization validations to ensure your devices arrive as intended to those who need them.

Validation Activities

Our robust validation processes include, but are not limited to:

- Advanced Product Quality Planning (APQP)

- Installation Qualification (IQ)

- Operational Qualification (OQ)

- Performance Qualification (PQ)

- Production Part Approval Process (PPAP)

- Process Failure, Modes, and Effects Analysis (PFMEA)

- Gauge Repeatability and Reproducibility (GR&R)

- Cleaning Validations

- Sterilization Validations

- Package Integrity & Seal Strength Testing

- Package Shelf Life Studies and Accelerated Aging

- Transportation and Distribution Testing

- Capability Analysis

- Validation Protocol Development

- Statistical Support for Validation Planning and Execution

- Assessment and Leveraging of Product Families

Have questions about our validation services?

Our Businesses

Laser Processing, Precision Stamping and Molding Technologies

CDT integrates manufacturing and engineering expertise across a broad range of capabilities to produce high-precision components and assemblies.

Finished Device Assembly, Kitting, Packaging and Sterilization Services

QTS offers critical end-of-line services for medical device OEMs including finished device assembly, packaging and sterilization management.

Precision Machining, Additive Manufacturing and Metal Fabrication

rms is a contract manufacturer of high-quality, tight-tolerance implantable devices, components, assemblies, custom instrumentation, metal enclosures, and cases & trays.