Phased Design Support

Leading You Through the Process

Depending on your project needs, we can provide full support from early design stages to complete medical device assembly.

Early involvement in the design cycle allows our experts to provide valuable Design for Manufacturability and Assembly (DFMA) input helping you avoid potential manufacturing failures. We utilize Failure Mode Effects Analysis (FMEA) throughout your tooling and process development to ensure we adhere to your production specifications in all possible outcomes.

Throughout the DFMA process, our manufacturing and quality engineering teams work with your designers, engineers and quality resources to finalize tolerances, design, measurement and verification requirements. This ensures your products can be manufactured to achieve the required performance in the most economical way.

Regular status meetings led by your project management team ensure we have a mutual understanding of your project scope and timeline. We will work to ensure your project is ready for production on-schedule with a streamlined manufacturing cycle.

Staged Gate Process

For highly complex and multi-faceted programs, our Cretex Medical | CDT team employs a staged-gate approach to manage product realization from prototype development through product launch. This process ensures you have input and approval every step of the way. We deliver optimal New Product Introduction (NPI) outcomes for our customers by combining experience, expertise and program management.

Our Stage Gates

- Determine Product Requirements

- Support Design Concept Selection

- Product Design Support

- Design Verification Support

- Process Validation (IQ/OQ/PQ, PPAP)

- Transfer to Production

Our Businesses

Laser Processing, Precision Stamping and Molding Technologies

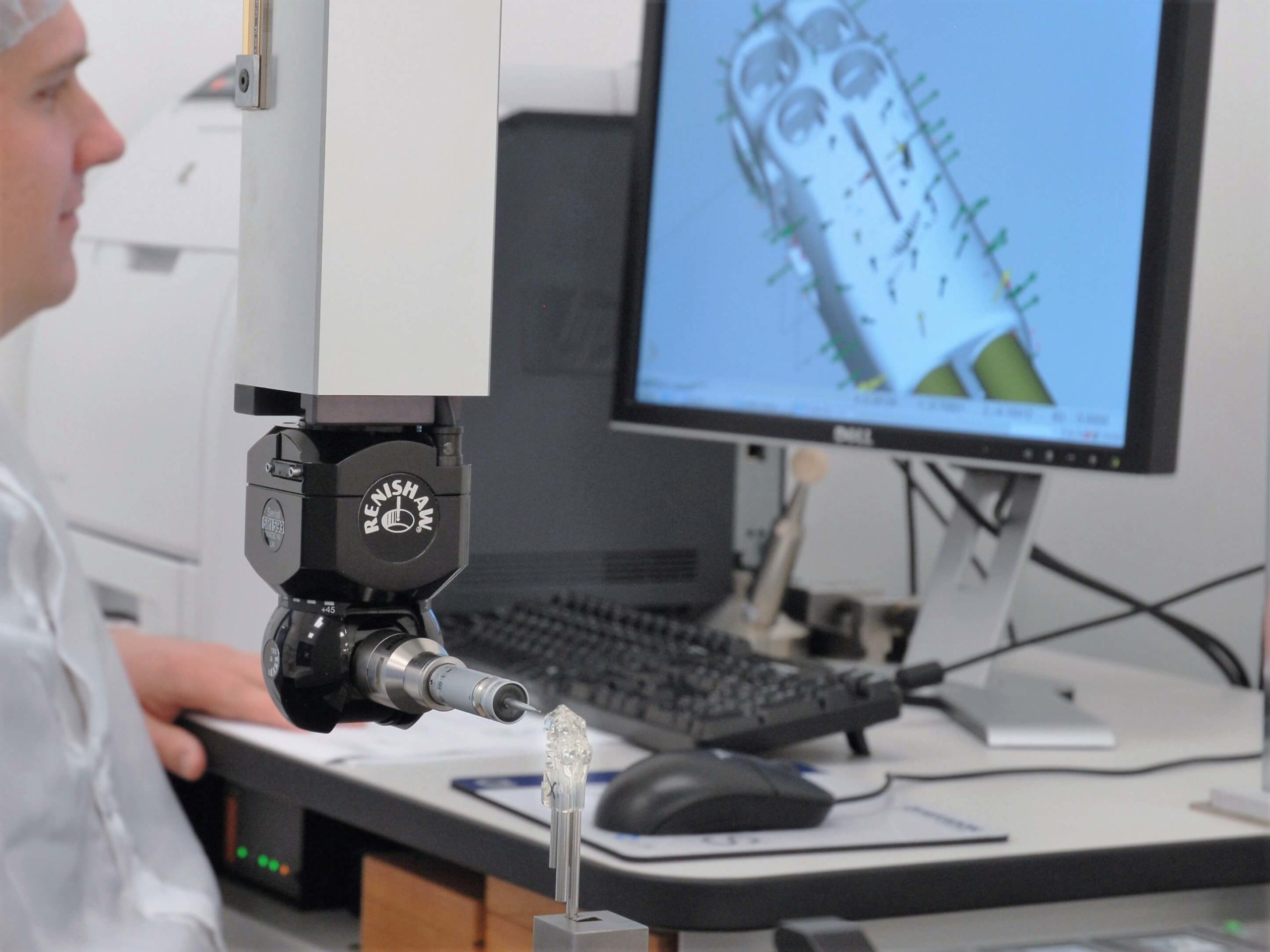

CDT integrates manufacturing and engineering expertise across a broad range of capabilities to produce high-precision components and assemblies.

Finished Device Assembly, Kitting, Packaging and Sterilization Services

QTS offers reliable end-of-line services including validated cleaning, sterile packaging, and complete kitting and labeling of your devices.

Precision Machining, Additive Manufacturing and Metal Fabrication

rms is a contract manufacturer of high-quality, tight-tolerance implantable devices, components, assemblies, custom instrumentation, metal enclosures, and cases & trays.