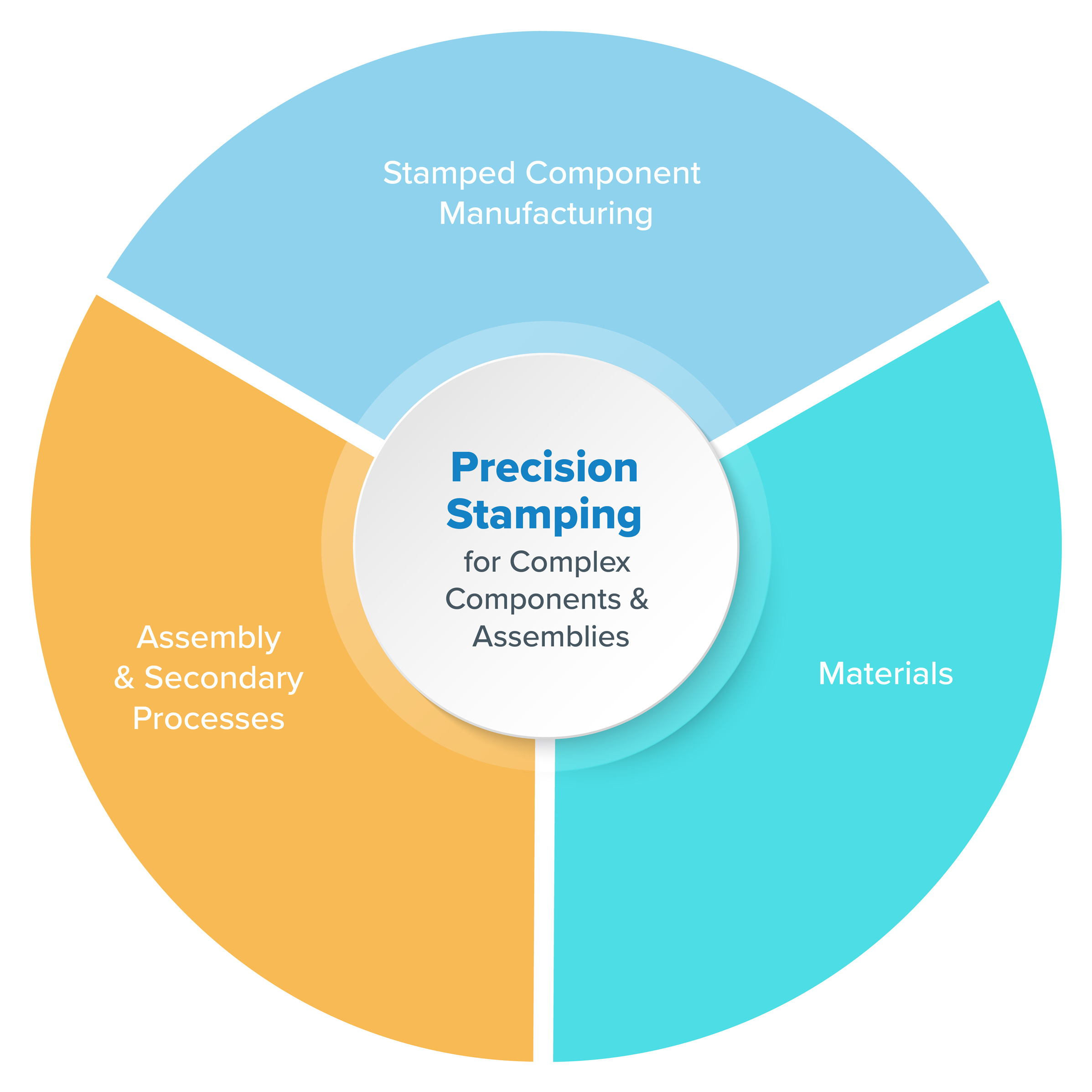

Stamping

Stamped Component Manufacturing

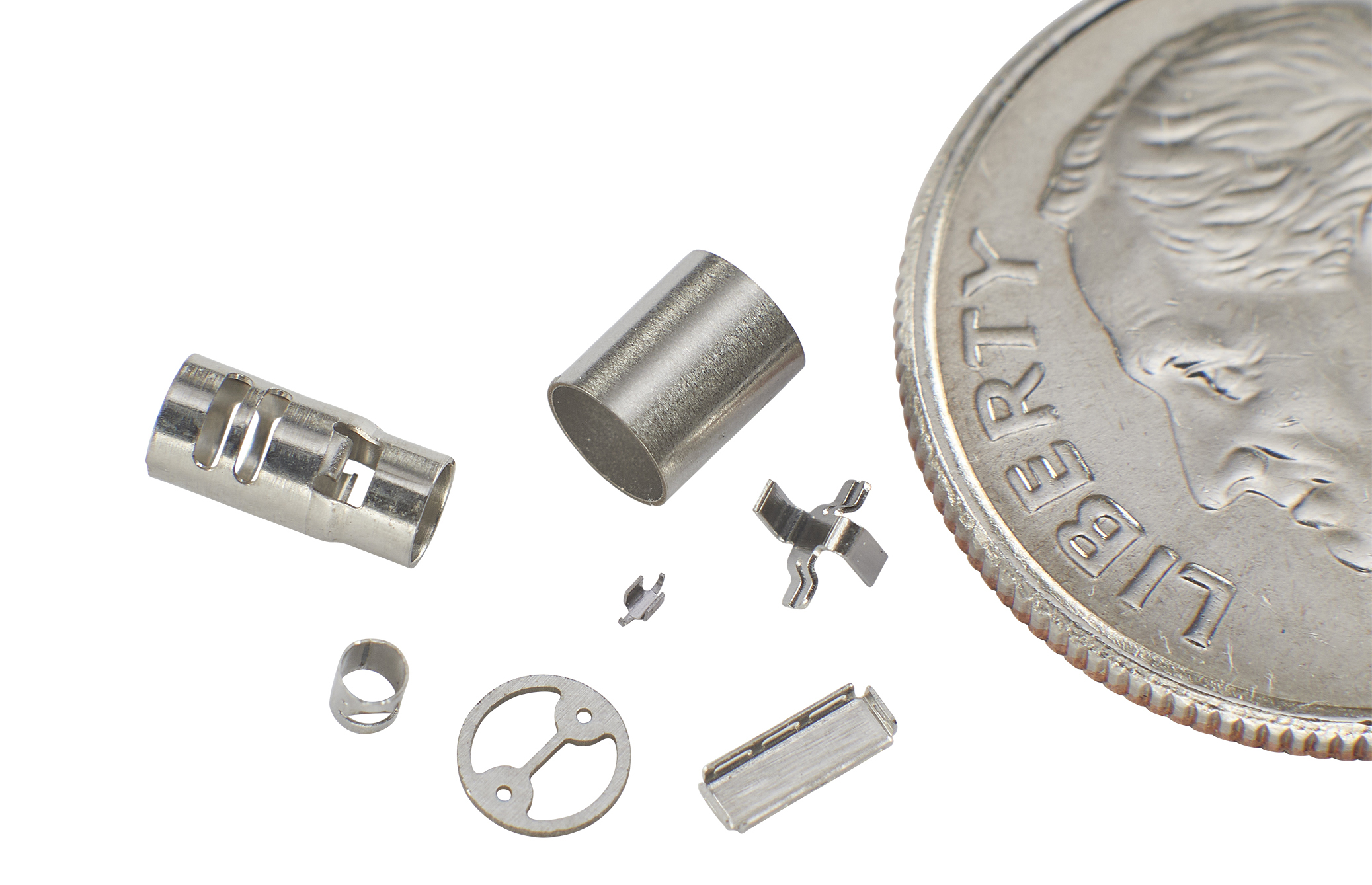

Complex Micro-Sized Components, Shallow and Deep-Drawn Cans and Case Halves for Today’s Medical Device Industry

Our team of stamping experts uses advanced technology to create high-quality progressive and automated transfer dies necessary to transform a simple metal strip into a complex finished component. We have the flexibility and know-how to handle any job, no matter how big or small. From a few dozen pieces, up to millions of components, we offer stamping options to meet your volume requirements.

Metal forming, including punching, coining and bending a large variety of unique metals, to produce the most efficient solution.

Short-Run Capabilities

Our in-house tool and die making and dedicated short run presses allow us to meet your low volume (20,000 components or fewer) production needs. While it may be a smaller project, we still bring high quality, fully validated tools to the table.

Our short run presses can handle projects with a variety of materials, sizes, and geometries.

High-Volume Production

As volumes increase, our processes drive greater and greater customer value. We’ve optimized the time-consuming quality testing process to ensure we meet production goals with dies that are extremely robust, retain their consistency, and exceed typical die life expectancy. Our continuous focus on Operational Excellence helps increase production, while reducing waste and controlling costs.

From small runs through production in the millions, we deliver a consistent level of quality and excellence.

High volume jobs could include components for single-use devices (SUDs) or biopsy tools such as jaws or needles.

In-House Tool Design, Build & Maintenance

With decades of tooling design and manufacturing expertise, our advanced in-house tooling team is equipped with modern CAD technology to produce the high-quality dies and fixtures used in our precision stamping and assembly operations.

Complete in-house CNC machining tool capability, including:

- WEDM (Wire EDM)

- SEDM (Sinker EDM)

- 3-axis milling

- Precision 3 and 5-axis milling

- Precision grinding

- Precision CMM

Stamping Applications

We supply precision stamped components for a wide spectrum of medical devices across multiple markets, including:

Implantable Devices and Components

- Anchor Tabs

- Weld Rings

- Ferrules

- Leads

- Electrodes, Micro-contacts and Antennas

- Orientation, Radiopaque and Stent Markers

- Marker Bands

- Cans, Capacitor Cans and Case-Halves

- Lids and Covers

Disposable Devices and Components

- Battery Tabs

- Biopsy Forceps Cups and Needles

- Surgical Jaws

- Surgical Scissor Blades, Bisector Blades and Blade Assemblies

- Clevis

- Ring Electrode Assemblies

- Restraint Bands

- Transmitter Contacts

Hearing Devices

- Analog Hearing Aid Components

- Artificial Cochlear Components

- Digital Hearing Aid Components

- Battery Contacts / Gold Plated Contacts

- Lead Frames

- Micro-contacts

- Variable Resistor Components

Assembly & Secondary Processes

Finishing Operations to Streamline Your Supply Chain

We have developed both in-house secondary operations capabilities as well as a network of approved suppliers that offer a complete range of finishing operations to best meet your custom component requirements.

Additionally, within our family of Cretex Medical companies customers have access to machined components, custom surgical instrumentation, sterilization case and tray products, finished device assembly, and sterile packaging, providing a truly comprehensive solution for most component and sub-assembly requirements.

Capabilities:

- Laser welding

- Tapping (threading of discrete parts or automated in-die tapping)

- CNC machining of pre-stamped blanks

- Wire EDM

- Staking (manual or automated in-die joining of components)

- Countersinking

- Grinding and Deburring (tumbling, cryogenics, harperizing and centrifugal)

- Plastic over-molding

- Plating

- Reel-to-reel plating of continuous pre-formed strips

- Post-plated rack or barrel of discrete parts

- Gold

- Platinum

- Silver

- Palladium

- Nickel

- Pre-processed precious metal inlayed strips

- Cleaning (ultrasonic) & Passivation

- Heat treatment

- Electropolishing

- Nitinol

- Elgiloy

- Anodizing

- Grit blasting and surface texturing

Product Examples:

- Orthopaedic and surgical instruments

- Ophthalmic surgical interfaces

- Critical header and lead subassemblies for cardiac rhythm management and neuromodulation devices

Materials

The Expertise and Variety to Meet Your Needs

With decades of stamping experience, we have the know-how to work with a wide range of metals. With a deep understanding of material properties and forming characteristics, we can help you find the best material solutions for your components.

Our Material Expertise Includes (but isn’t limited to):

Alloys

- Beryllium Copper

- Brass

- Cobalt Chrome

- Elgiloy

- Inconel

- Kovar

- MP35N

- Nickel 200

- Nitinol

- Permanickel

- Phosphorus Bronze

- Spring Steels

- Stainless Steel

- 300 Series

- 400 Series

- 17-7 Materials

- Tantalum

- Titanium / Titanium Alloys

- Tungsten

Precious Metals

- Gold

- Gold Foil Inlaid

- Gold Plated

- Iridium

- Platinum

- 99.9%

- Platinum Iridium Alloys

- Silver

Metals

- Aluminum

- Copper

- Hastelloy

- Iron

- Magnesium

Material Thickness

.002” through .125”

Tolerances

.0005”