Improve your Manufacturing Process through Ergonomics

Applying ergonomic principles in your manufacturing process can benefit your bottom line in some surprising ways. Not only can you protect your employees and reduce downtime, but you can also improve employee comfort, increase job satisfaction, and positively impact retention. Implementing ergonomic principles can also increase efficiency, help manage costs, and reduce time to market.

Reduce Risk Factors

Observe your manufacturing processes for areas that require operators to perform repetitive, strenuous, or unnatural movements. Think about changes you can make to either reduce the need for repetitive movements or make the movements more comfortable for operators. This can be as simple as making a small change to the layout of the production line or as complex as incorporating automation into the production process.

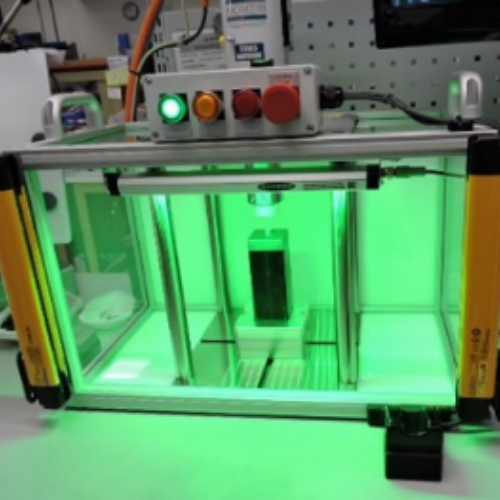

rms Company reduced repetitive movements for operators in the production of spinal screws by automating an arbor press used to secure the assembly of the compression ring and housing structure. Previously, the operator had to reach above their head and pull down to use the press posing a risk for shoulder over-extensions and injury. By automating this process, rms improved quality by providing added control of torque and pressure, eliminated the risk for potential injuries, and increased productivity by reducing cycle time by six seconds, a total of 200 hours annually!

Improve Employee Satisfaction

Look for areas in your production process where you can improve ease and comfort and make the process more enjoyable for operators. Making changes to employee workstations and production line layout can have a positive impact on workflow and work environment.

rms Company recently completely overhauled the deburring area in their secondary operations department. Employees now have adjustable stations with the option to perform their work standing and ergonomic seating ensuring proper height from the floor. Each workstation also has a vacuum pipe to eliminate fume and dust exposure. changes reduce risk for strain and injury and improve the work experience for employees.

Increase Efficiency

When looking to incorporate ergonomic principles in your production process, seek a win-win situation. Implementing ergonomic principles should simultaneously improve production and elevate employee safety and comfort.

Analyze areas in the production process in which you can increase efficiency. Many times, increasing efficiency in a production process will make the process more ergonomic. These changes do not have to be drastic to have a significant impact – small, incremental changes can also make a positive difference. QTS made a simple adjustment to a part presenter tray from right-angled corners to rounded corners. This made small parts easier for assemblers to pick up. They also added dividers which made it easier for assemblers to organize parts. These minor changes made a significant change in work experience and increased productivity by five percent!

Incorporating ergonomic principles in your production process has never been easier. Recent advances in Artificial Intelligence (AI) software have made it simple to perform in-depth ergonomic evaluations and make informed decisions for your employees and products.

Utilizing ergonomics can eliminate downtime, reduce risk for employee injuries, and facilitate more efficient production while maintaining, or even improving, quality so you can get your products to the people who need them, when they need them.