Stamping

Transforming Critical Metal Parts

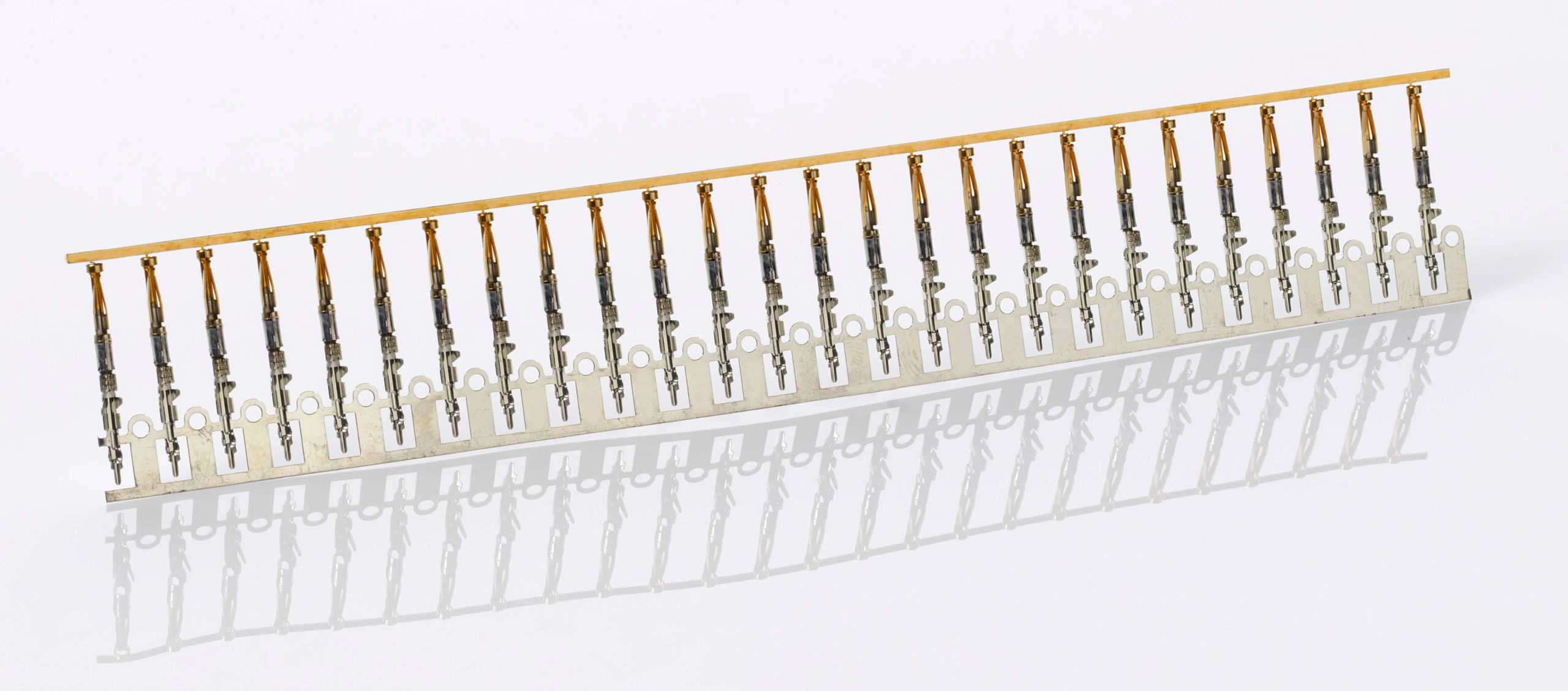

Cretex Medical | CDT offers precision metal stampings and secondary assemblies. Our experienced in-house toolmakers and engineers utilize advanced forming techniques to enable us to customize each stamped component. It doesn’t have to be flat to be stamped – and selecting the right production path is critical to ensuring the success of your project throughout the product lifecycle.

Dependable Quality for Your Most Critical Applications

Throughout our decades in business, Cretex Medical has successfully transformed over a billion critical, close-tolerance stamped metal components for the highly regulated medical device industry. Our engineering ingenuity and innovative design solutions provide alternatives for transforming costly machined components into high-quality, precision metal stamped parts at a fraction of the cost.

CDT stamping experts are skilled in working with a wide variety of metals and engineered materials. We can assist you in selecting the optimal material solutions for your components, ensuring the success of your project.

Our Businesses

Laser Processing, Precision Stamping and Molding Technologies

CDT integrates manufacturing and engineering expertise across a broad range of capabilities to produce high-precision components and assemblies.

Finished Device Assembly, Kitting, Packaging and Sterilization Services

QTS offers reliable end-of-line services including validated cleaning, sterile packaging, and complete kitting and labeling of your devices.

Precision Machining, Additive Manufacturing and Metal Fabrication

rms is a contract manufacturer of high-quality, tight-tolerance implantable devices, components, assemblies, custom instrumentation, metal enclosures, and cases & trays.