Metal Fabrication

Sterilization Delivery Systems

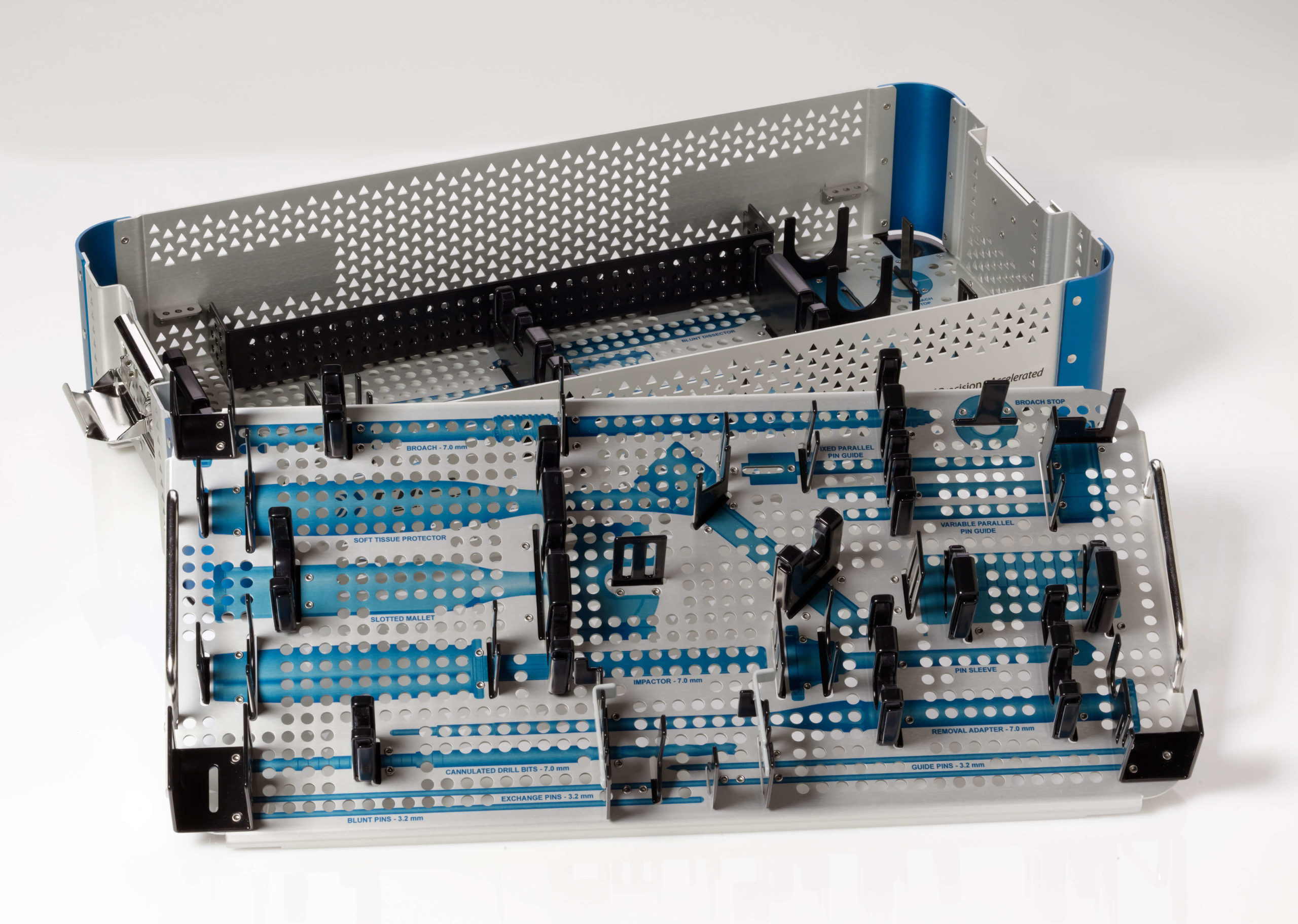

Our 110,000 sq. ft. manufacturing facility in Anoka, MN, draws on decades of metal fabrication expertise to design and produce custom surgical instrument trays and sterilization cases. Our fabrication capabilities provide you with options for hybrid designs, single or multilevel stackable sterilization cases, trays, caddies and nests.

You need a partner with expertise in design for manufacturability (DFM) who can provide critical analysis to ensure optimal design strength and efficient manufacturing processes. Our experts are dedicated to maximizing the number of instruments in each case while maintaining proper airflow and drying time, and they will work with you to reduce weight in your design without jeopardizing structural integrity.

Metal Fabrication Beyond Cases & Trays

Cretex Medical | rms can also help you with specialized metal enclosures for your medical devices and equipment. Our precision manufacturing processes ensure your products meet the exacting standards required by the medical industry. Our robust quality system paired with our ISO 13485 certification and FDA registration give you peace of mind knowing your product will perform at the highest levels.

Did you know we can manufacture your surgical instruments too?

Our Businesses

Laser Processing, Precision Stamping and Molding Technologies

CDT integrates manufacturing and engineering expertise across a broad range of capabilities to produce high-precision components and assemblies.

Finished Device Assembly, Kitting, Packaging and Sterilization Services

QTS offers critical end-of-line services for medical device OEMs including finished device assembly, packaging and sterilization management.

Precision Machining, Additive Manufacturing and Metal Fabrication

rms is a contract manufacturer of high-quality, tight-tolerance implantable devices, components, assemblies, custom instrumentation, metal enclosures, and cases & trays.